液压振动打桩锤关键术语

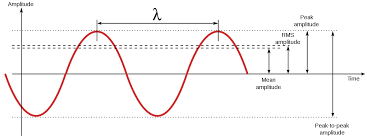

它是在振动打桩锤在上下振动中测量的周期性振动的宽度。

振幅是选择振动锤的关键因素,它必须高于沙子,对于粘土应在3~6mm之间。

振动锤的振幅的一般描述是应该在6~12mm之间。

振幅将垂直传播以在每次振动时将土壤剪切掉。

It is called as‘Steel Tube Pile’or‘Tubular Pile’by many workers on sites,but the leading reason for calling a Caisson Pile is that it’s for typically in the Caisson foundation by using the Vibro Hammer operation.This pile is manufactured in seamless spirally welded or well lap-welded and is normally installed by top driving but in difficult ground conditions and also it can be installed by a combination of drill and drive.This pile is born as a watertight retaining structure used for,for example,to work on the foundation of a bridge pier,for the construction of concrete dam or for the repair of ships.These are constructed such that the water can be pumped out,keeping the environment dry and is sunk into the ground to some desired depth and then filled with concrete thus forming a foundation that this is because Caissons can be floated to the job site.The types of Caissons are varied like Box type,Excavated type,Open type,Pneumatic type and Caisson Sheet Pile.

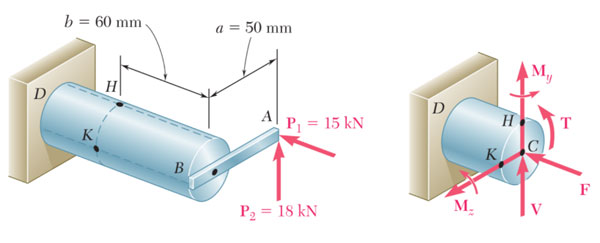

A pile driven on angle driving in an angle to the vertical,and it is normally used for counteracting its horizontal force acting on vertical piles

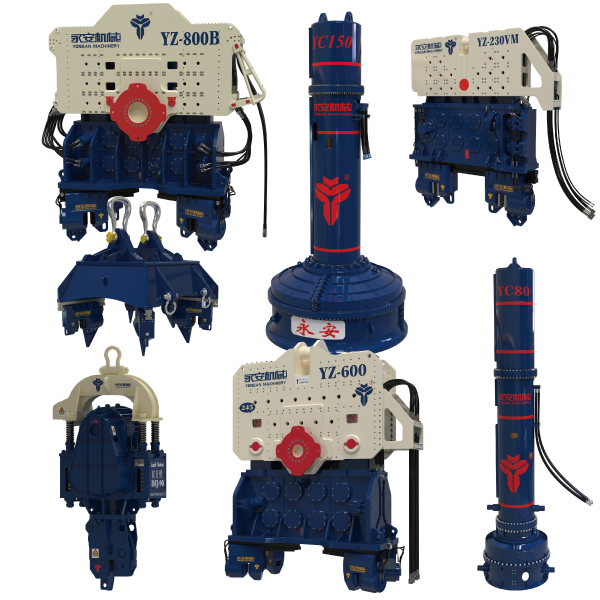

It is one of main part of Vibro Hammer attached to on bottom of Vibro body to conduct a practical Vibro operation after it grabs the piles.The clamp contains two gripping jaws,one is“fixed”and one is“movable”.A large hydraulic cylinder in the Clap operates the moveable jaw with up to designed power tons of clamping force depending on clamp pump relief pressure.The jaws open and close by turning a switch on the remote control pendant,or may be operated by turning the switch at the main control panel,mounted behind one of the doors on the power unit.The check valve automatically operates the clamp flows either the direction Close or Open.Clamp types provided by Yongan are varied,among them the Universal type,which is also called as‘Single Clamp’and Caisson Clamp which is also called as‘Double Clamp’are the most representing Clamp released by Yongan.

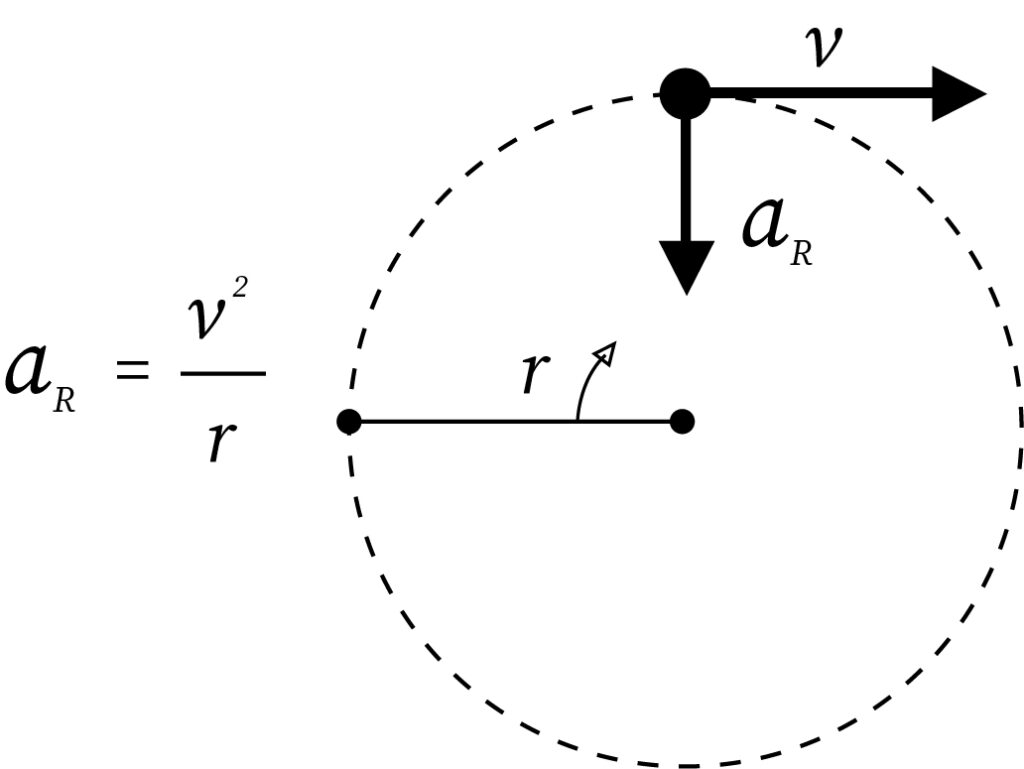

It is important key factor that decides the Vibro performance.It is generated by rotating Eccentric Weights inside the Gearbox shaped like a half moon and it is connected with other components by Gears and Shaft to create the moment.A small increased speed can turned out a large increasingly developed Centrifugal Force and this force is generally measured in tons by Yongan Vibro Hammer.are the most representing Clamp released by Yongan.

偏心力矩是衡量一个振动打桩锤打桩能力的第一参数。

振动打桩锤偏心块高速旋转的偏心力矩必须产生足够大的振幅需要超过各种土壤的弹性范围。

只有偏心力矩足够大,振幅才能和振动打桩锤的打桩能力画上等号。

偏心力矩是偏心块轴向旋转所产生的有效打桩能量。

这个参数值和偏心块重量乘以偏心块重力线到轴中心线的距离,然后乘以振动锤齿轮箱的偏心块数量。

It is the area of piston rod head of the clamp multiplied by the available Clamp Pressure of the Power Pack.The Clamp Force is very important to the life of Jaws of the Clamp.

Adding an Extra Weight to the Static Weight of Vibro can increase the Vibro performance resulting in more deeper and faster penetration especially,when the Vibro need to vibrate a firm clay soil although it is less effective in sand.This is because the Centrifugal Force must overcome its resistance under the pile,where the friction of clay soil would be reduced by the Amplitude.In general,unfavorable result can be brought in sand when a total static weight of Vibro is more than the Dynamic Weight of Vibro.

It is also called as’Normal Frequency Vibro’or‘Standard Vibro Hammer’by many others among Vibro manufacturing company.The Frequency range of Fixed Moment Vibro Hammers are specified on the average between 1600~2200 vpm to conduct a standard Vibro work.Regardless of Fixed Moment type or Variable Moment type,all the Vibro Hammer is consisting of three main components,which are Suppressor Housing,Gearbox Assembly and Clamp Assembly.The Eccentric Weights In the Gearbox rotates in a vertical plane to create vibration driven by hydraulic motors mounted on Gearbox Assembly where two of both are connected each other to keep them a proper synchronization that creates vertical vibration.The vibration can be transmitted into pile being driven by means Clamp

In physics,it means that the number of cycles or completed alternation per unit time of a wave or oscillation,but in Vibro terms,it is the vibration per minute(vpm)and speed of rotating eccentric weights

It means that the overall weight of the Vibro Hammer in Combination with its Frequency and Centrifugal Force that helps to drive a pile